Article reposted with permission from Label and Narrow Web.

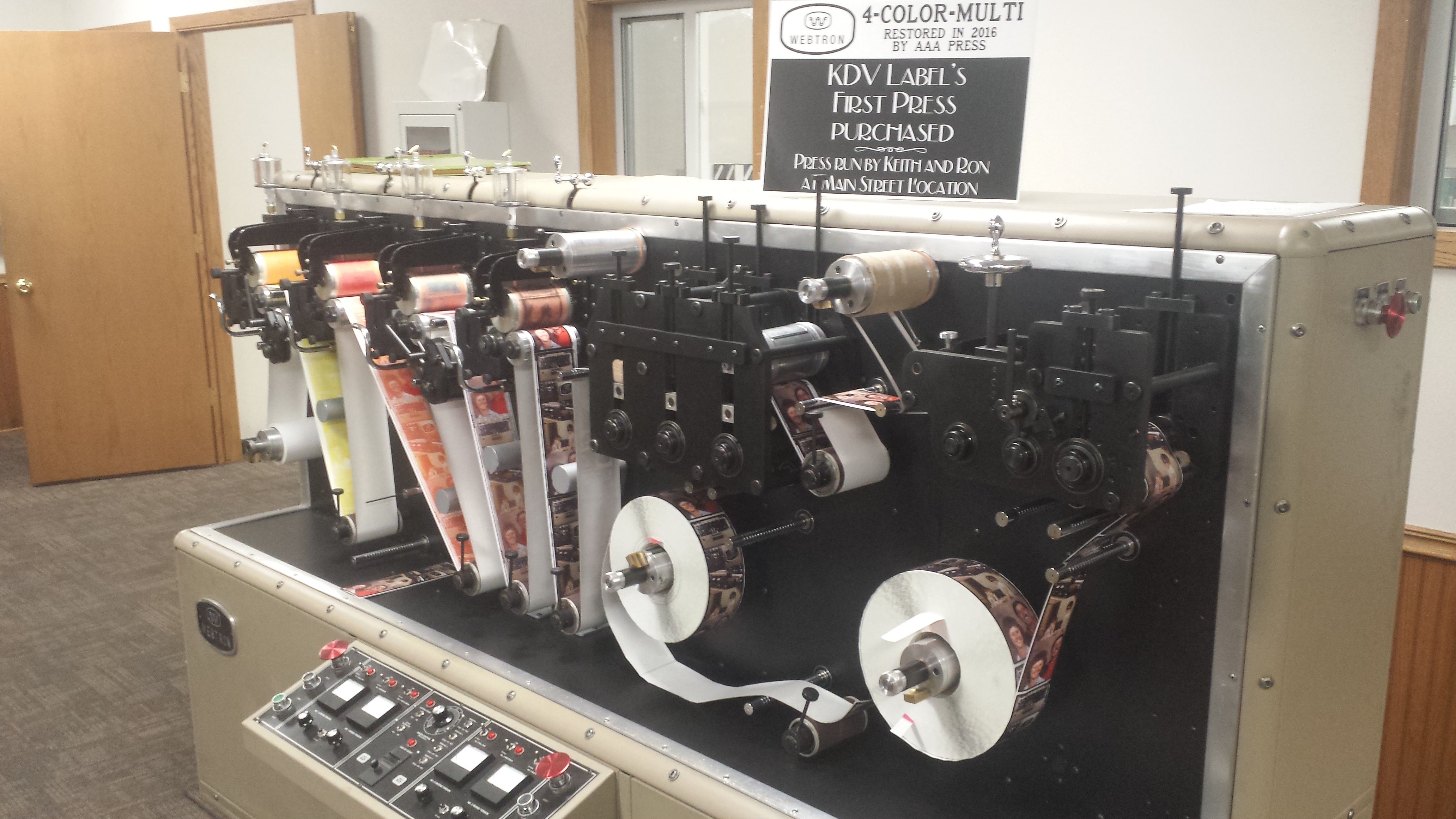

In a process likened to the restoration of a vintage car, KDV Label, based in Waukesha, WI, USA, went to AAA Press to fully recondition a Webtron 450 (4.5″ wide) narrow web flexo press. KDV is one of AAA Press’ original customers. AAA Press, founded in 1986, is a full-service supplier to the flexographic industry, offering press parts, field service, supplies, equipment, UV curing systems, IR drying systems and accessories. The company buys and sells more than 20 pieces of equipment per month, provides on-site field service with factory trained technicians and subcontractors located throughout the United States. Ed Klein, service manager, performed the bulk of the work on KDV’s press, which dates back to the early 1960s. “It was the first narrow web flexo press I ever ran,” says Dick Vaughn, chief executive officer, KDV. “It’s history, memories – something we wanted to try to do. It’s where we got started and how we got started. Webtron, back in the day, was the best press on the market. It was the Cadillac out there, by far.” Currently, KDV has 13 presses with max speeds around 700 fpm. The Webtron 450 operated at top speeds of 300 fpm, which was a vast improvement at the time. Prior to the Webtron, the average press ran at 100 fpm. The single-color press was used to print meat, cheese and beer labels, among others. It printed fine type with a rubber plate, and some of the labels included foil. “It’s like rebuilding an old car,” explains Mark Hahn, vice president of sales and marketing at AAA Press. “This is one of the first ones they made. Everything is all mechanical, but it’s kind of neat. When you look at a press today, it’s just different. Just trying to find parts for this project was challenging. It took a year to get them and many had to be custom made.”

From left, Jack Ludwig of AAA Press, KDV Label CEO Dick Vaughn, and Shane Vaughn, president of KDV Label

The restoration process provided a trip down Memory Lane for those associated with KDV. Vaughn established the company with his wife, Karen, in 1974. They originally found a niche in the dairy industry but have expanded to supply labels for beverage, food, nutraceuticals, chemical and petroleum, and specialty promotional product markets.

Dick’s son, Shane, oversees the business as its president. The company has undergone several expansions, with the most recent one a 22,000 square-foot addition, pushing its space to 85,000 square feet. All of the operations are performed in-house, from artwork, to platemaking, to finishing. According to KDV, the expansion provided workflow efficiency and enabled the company to better meet the needs of its customers.

The modern-day equipment at KDV provides perspective for the Webtron 450, which is over 50 years old. “The Webtron looks small, but there’s a lot of work in that small piece of machinery,” says Todd Zweifel, maintenance supervisor at KDV. “Basically, today, a finished product comes off the end, whereas with the Webtron, you’ve got to take this one step at a time. Now, from start to finish, the product comes off and it’s ready to go in a box and be shipped off to customers.” In addition to digital prepress and CTP technology, KDV went live with a new fully integrated computer system in 2009. That same year, the company installed a computerized automated ink mixing system to improve accuracy and reduce waste. KDV has committed to reducing its carbon footprint and becoming more environmentally sound in the last five years, as well. At KDV, label manufacturing takes place 24-hours a day for six days during the week. “We’ve reconditioned hundreds and hundreds of presses, just not to this degree,” says Jack Ludwig, president at AAA Press. “I’ve been in the industry since 1971, so this has been around longer than me. It is kind of unique, and that’s why we thought it was a great story because the press is over 50 years old. That’s what [Vaughn] started printing on and when he came to us with the project; we loved the idea. It just takes a lot of time to get a lot of the parts and custom-make the parts. We loved it, though. It was a fun project.”

KDV Label’s Mark Andy Performance Series press

Vaughn opened KDV Label with a four-color Multiflex, which was an extension of the Webtron. “It was pretty innovative when they came out with this Webtron, and it was so successful that they expanded it into a four-color press,” adds Ludwig. “Single diecutting was it, and even that was innovative. Even the Multiflex had three die stations, plus a sheeting station for sheeted labels, so it was all inline.” Through the years, AAA Press, located in Arlington Heights, IL, USA, has worked closely with KDV. The company maintains anywhere from 1,600 to 1,800 SKUs of Webtron press parts. In addition to brokering used equipment and housing an inventory of older parts, AAA Press manufactures the Lightouch UV curing system and Maximizer Infrared drying system. KDV utilizes the Lightouch UV curing system on it≠s presses. Along with the Maximizer IR drying system, AAA Press has more than 3,700 systems in service around the world. The Lightouch system features two electronic controller options, which include the Versiflex model for most standard applications and the Microstep model for tighter UV intensity control.